A1706 Rongding building xinhua district shijiazhuang city hebei province China +86-311-68003825 [email protected]

Flooring systems made with epoxy flakes tend to break down about 3.7 times quicker if they come from companies without proper certification, as shown in research on coating durability published last year. The top tier manufacturers employ special closed loop systems for cleaning resins, cutting down on tiny particles that get into the mix by nearly 90% over standard approaches. This makes all the difference when it comes to getting those 15 to 20 years out of garage floors and factory floors where people actually need them to last through daily wear and tear.

Top-grade manufacturers maintain a 2% variance in flake thickness through mineral-reinforced polymer extrusion technology. This precision prevents edge-lifting and color banding caused by irregular flake geometries. Specifiers should verify raw material origins — domestically mined silica substrates typically demonstrate 34% higher UV resistance than imported alternatives in accelerated weathering tests.

Four essential benchmarks separate market leaders:

| Certification | Quality Impact | Testing Frequency |

|---|---|---|

| ISO 9001:2015 | 41% fewer batch inconsistencies | Quarterly audits |

| ASTM D6944 | 2.8x better abrasion resistance | Annual validation |

| ISO 14001 | 78% lower VOC content | Continuous monitoring |

The ISO 9001 certification process mandates statistical process control at all manufacturing stages, ensuring color uniformity across production runs. Leading plants now incorporate AI-driven spectrometers that analyze 12,000 flakes per minute for dimensional compliance — a 15x improvement over traditional sampling methods.

Durability and chemical resistance define the operational lifespan of epoxy flake coatings. Industrial floors face cumulative stress from abrasion, chemical spills, and thermal fluctuations, making material science fundamentals critical in manufacturer selection.

The way epoxy molecules link together affects how well it stands up to wear and tear. Recent research in polymer science back in 2024 showed something interesting about this. When manufacturers optimize their amine-cured formulas, these special epoxies can handle almost 40% more abrasion tests according to ASTM standards compared to regular mixtures. What makes epoxy so good at resisting chemicals? It comes down to those water-repelling molecular chains that push away things like acid, oil, and various solvents. For temperature performance, we look at what's called the glass transition temperature or Tg. Coatings that meet or exceed 65 degrees Celsius in Tg testing (as specified by ISO 11357-2) generally hold their shape and function properly even when exposed to extreme conditions from as cold as minus 40 degrees all the way up to 120 degrees Celsius.

Over twelve months, researchers looked at twenty five auto repair shops and found something interesting about their floors. Epoxy surfaces with those dense flake systems held up against hydraulic fluids much better than regular coatings did actually resisting them about eighty three percent more effectively. Shops that went for chemical resistant formulas saw far fewer problems with joints coming apart too around ninety one percent less delamination when compared to standard products on the market. This matches what other industry research has shown about epoxy flooring. When manufacturers get the mix right between resin and hardener components, they can stop issues like swelling and color changes caused by motor oil getting into the floor over time.

Third-party validation separates marketing claims from performance reality. Reputable manufacturers provide:

Always request batch-specific test reports dated within six months to verify current production quality.

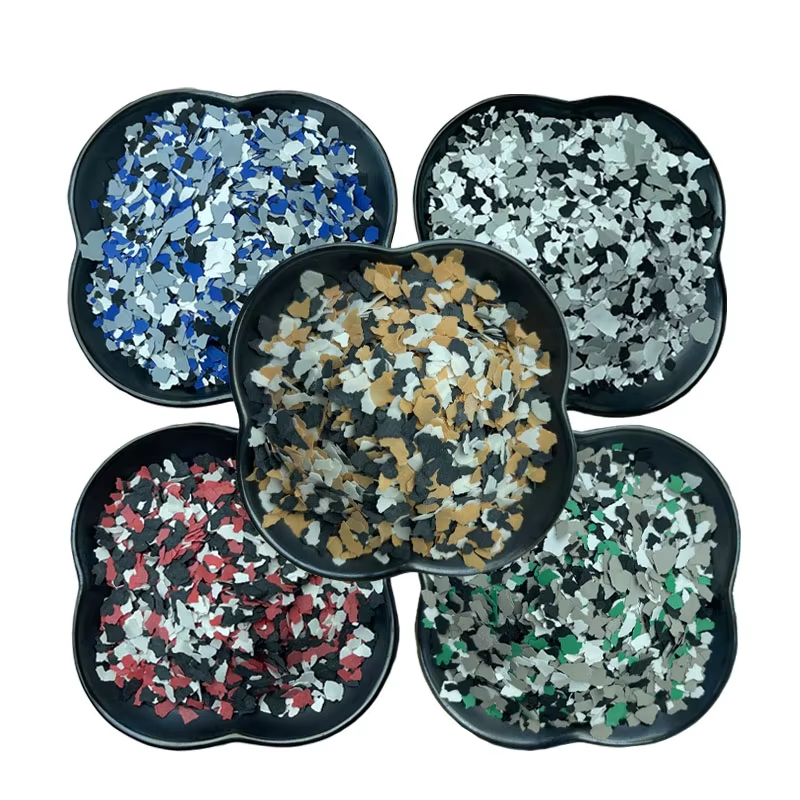

Design discrepancies often occur when basecoat colors interact unexpectedly with epoxy flake dispersion patterns. Light-colored basecoats may wash out vibrant flakes under LED lighting, while dark primers can intensify metallic finishes beyond digital renderings. These mismatches underscore why professionals prioritize material interaction analysis from the planning phase.

In industrial environments where slip resistance is important and hiding wear matters, go with smaller acrylic resin flakes around 0.5 to 1mm. These little guys actually last about 40% longer under forklift traffic according to ASTM tests, which makes them pretty tough for warehouses and factories. When it comes to retail areas though, bigger is better. Vinyl chips measuring 3 to 5mm give floors that nice dimensional look while still being easy to clean. The best results come from neutral color blends mixing two or three similar shades together. This approach hides those inevitable scuff marks much better than sticking with just one solid color would.

It's essential to test those UV stable sample boards under whatever lighting conditions exist in the actual installation space. Flooring experts note this simple step gets overlooked in roughly 3 out of every 10 failed installations based on their latest industry reports from 2024. Most top brands now offer custom mockups that let specifiers see exactly how different flake density levels work with various base coat colors. The numbers back it up too. When teams actually handle physical samples before finalizing decisions, they end up making about two thirds fewer changes after installation than when relying solely on digital images for approval. Makes sense really since nothing beats seeing materials in real light conditions.

Standardized epoxy flake systems struggle in environments with extreme temperature fluctuations, chemical exposure, or heavy mechanical wear. A 2023 coatings industry study revealed that 37% of floor coating failures in food processing plants stemmed from incompatible flake formulations for wet, acidic environments.

| Flake Size Range | Ideal Applications | Durability Impact |

|---|---|---|

| 0.2–1.2 mm | Decorative residential | Moderate wear resistance |

| 1.5–3.5 mm | Industrial/commercial | High slip/abrasion resistance |

| 4.0–6.0 mm | Specialty (aircraft hangars) | Extreme chemical tolerance |

Leading manufacturers now offer blend-on-demand systems, allowing precise ratios of metallic and quartz flakes. Recent data shows customizable systems outperform generic alternatives by 62% in salt spray tests (ASTM B117-2024).

Seek partners with in-house R&D labs and material traceability systems. A 2024 Industrial Materials Customization Report found 82% of specialty contractors prioritize manufacturers offering viscosity adjustments (±5%) and flake density customization (8–25 oz/gal). Verify batch-specific technical data sheets and request scaled-down trial mixes before full production runs.

The current global supply chain issues are causing serious delays in getting epoxy flakes delivered, sometimes stretching wait times out to between four and eight weeks based on what the polymer industry reported last year. For anyone dealing with epoxy flake producers, it's worth checking how they handle backup plans for storing raw materials and having alternative transportation options available. The situation gets even trickier when projects need specific color matches for flake blends. Missing just one type of pigment can bring whole manufacturing operations to a standstill, which is why many companies are now looking at their supplier relationships through a completely different lens.

Top manufacturers achieve <3% variance in flake thickness across production batches through automated material inspection systems. Require certificates documenting quartz aggregate origins and resin purification methods. Field tests show inconsistent flake geometry — common with unstable mineral sourcing — reduces coating durability by 27% in high-traffic environments.

When looking at potential partners, ask for evidence they track inventory in real time along with records showing what materials were available over the past year. Companies that keep about six months worth of essential binders and additives on hand tend to face far fewer supply issues than those relying solely on just-in-time delivery systems. Some studies suggest these buffer stocks cut down on shortages by roughly three quarters. Take a close look at how they vet their suppliers too. Top performers don't just check boxes once in a while but actually conduct regular audits of their secondary vendors every three months or so. These checks focus not only on whether suppliers meet ISO 9001 standards but also examine if they follow responsible sourcing practices throughout their supply chain.

Hot News

Hot News2025-12-21

2025-12-15

2025-12-05

2025-12-02

2025-12-01

2025-11-19