A1706 Rongding building xinhua district shijiazhuang city hebei province China +86-311-68003825 [email protected]

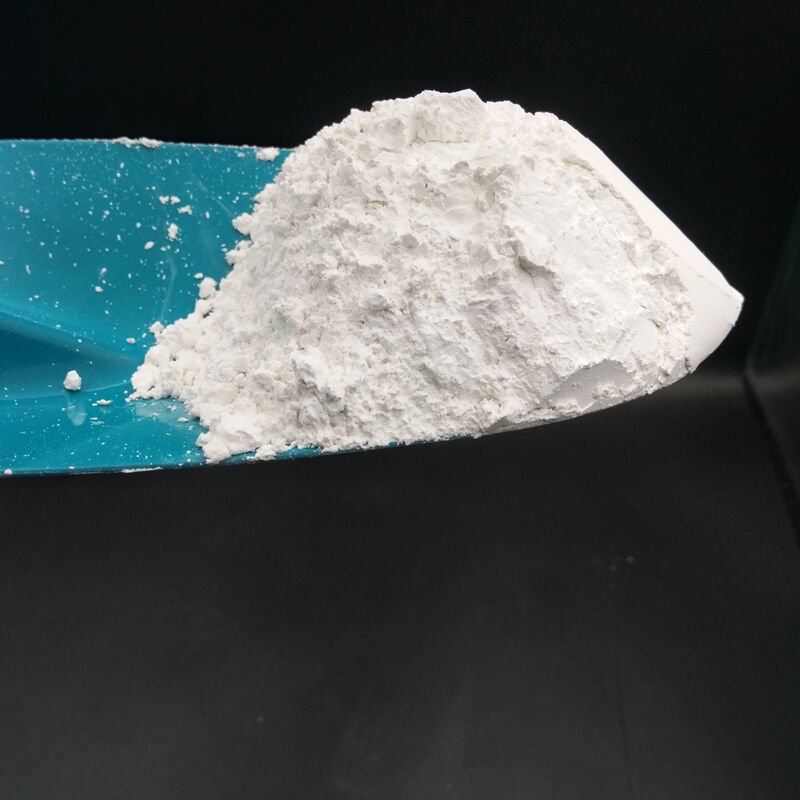

Bentonite of high quality serves as a base component in many heavy industries because of how much it can swell when wet. The stuff can soak up around ten times its own weight in water, which makes it really useful for various applications. When working in oil and gas drilling operations, bentonite helps keep those deep holes stable while also flushing out all the rock fragments that get cut during drilling. Foundry workers rely on this clay's strong binding properties to make their sand molds last longer. Using good quality bentonite actually cuts down on casting flaws by somewhere between 15 percent and 20 percent over cheaper options. For iron ore processing plants, bentonite plays another critical role as a binder substance. It allows them to create consistent pellets that hold together even when exposed to intense heat inside furnaces reaching temperatures as high as 1200 degrees Celsius without falling apart structurally.

Water treatment plants across the country rely on bentonite because it sticks to stuff really well. This clay removes nasty stuff like lead and arsenic from drinking water, taking out around 85 to almost 92 percent of these harmful substances. For environmental engineers dealing with contaminated groundwater, they often create barriers using sodium bentonite slurry that keeps pollutants from spreading further. The clay's ability to hold onto positively charged particles makes it great for cleaning up polluted sites too, since it traps toxins without stopping helpful bacteria from doing their job. We've seen some interesting developments lately where mixing calcium bentonite with other materials has made it possible to manage stormwater runoff in a more eco-friendly way, something many cities are starting to adopt as part of their green infrastructure plans.

Decarbonization efforts are increasing demand for bentonite in lithium-ion battery recycling, where it captures 97% of fluorine emissions during pyrometallurgical processing. In construction, bentonite-enhanced geopolymers reduce cement-related CO emissions by 30–40%. Nano-modified bentonites are now being adopted in geothermal drilling, demonstrating 18% greater fracture resistance at 300°C than conventional grades.

The ability of bentonite to swell and absorb liquids plays a big role in how well it works for sealing jobs, holding fluids, and acting as a binder. High quality bentonite products typically take in around five to ten times their own weight when soaked in water. The material expands significantly too, sometimes growing fifteen times larger than its original size, which creates those tight seals we need. Research published last year in Applied Clay Science found something interesting about this stuff. When the clay contains at least 85% montmorillonite, it swells about 25% faster compared to lower quality options. This matters quite a bit for things like landfill lining systems where proper expansion is critical, as well as in oil drilling operations where bentonite forms part of the mud mixture used during extraction processes.

The cation exchange capacity basically tells us how reactive bentonite will be when used in wastewater treatment processes and for making pellets. When we look at grades above 80 meq per 100 grams (tested using ammonium acetate techniques), these materials tend to perform best at removing contaminants and creating durable pellets. According to studies published in top materials science publications, bentonites with higher CEC values can cut down on the amount of iron ore binder needed by about 18 percent, all while still hitting the required ISO 4700 standards for pellet strength. This kind of performance makes them particularly attractive for industrial applications where both efficiency and quality matter.

| Property | Industrial-Grade Threshold | Testing Standard |

|---|---|---|

| Montmorillonite | ≥75% | XRD Analysis (ASTM D4318) |

| Quartz | ≤5% | XRF Spectroscopy |

| Organic Matter | ≤1% | Loss on Ignition (LOI) |

Impurities such as quartz or carbonates compromise thermal stability in foundry applications, while excess organic matter accelerates fluid breakdown in drilling environments.

Top-tier bentonite achieves over 30 cP viscosity in 6% suspensions under API 13A standards, ensuring effective cuttings transport and wellbore stability. In metal casting, its shear-thinning behavior allows dense mold compaction without cracking—reducing casting defects by up to 40% when compared to synthetic binders, according to the Metalcasting Journal (2024).

When looking at bentonite quality, industrial buyers need to check several things: grading systems, proper certifications, and actual performance data from real world applications. Most serious manufacturers stick to international standards like API Spec 13A and ASTM C837 when categorizing their products for different industries. These aren't just random numbers on paper either. The specs actually measure important characteristics such as how thick the slurry gets (viscosity), what kind of pressure resistance it offers (yield point), and how much liquid escapes during operation (fluid loss). Getting these right makes all the difference between smooth operations and costly problems downhole or in casting operations.

The American Petroleum Institute (API) and ASTM International enforce rigorous testing protocols for industrial applications. For example, API-certified bentonite must yield a minimum of 15 barrels per ton in freshwater to qualify for drilling fluid use.

Third-party labs employ advanced techniques to ensure consistency:

A 2024 Clay Mineral Standards Report found that suppliers using these methods reduced batch variability by 62% compared to those relying solely on basic density checks.

While natural calcium bentonite suits agricultural and low-swelling applications, most industrial processes require sodium-activated variants for superior hydration and dispersion. Processed grades should be accompanied by ISO 9001 certification detailing activation procedures and additive ratios to guarantee repeatability in critical operations like metal casting and wastewater treatment.

Reliable suppliers provide full mine-to-facility traceability and comply with SDS requirements. Those adhering to the Global Clay Sustainability Initiative reduce contamination risks by 38% and enhance delivery reliability for time-sensitive processes such as iron ore pelletization.

Premium sodium bentonite improves drilling fluid viscosity by 30%, creating robust wellbore walls that prevent collapse in shale formations (IADC Report 2023). Operators using high-quality bentonite reduce non-productive time by 25%, with slurry yields exceeding 90 barrels per ton in directional drilling applications.

Industrial trials show bentonite-rich binder systems reduce casting defects by 45% in automotive component production (AFS 2022). This improvement stems from excellent thermal stability (up to 1,450°C) and balanced green compression strength (120–150 kPa), which minimize sand burn-on and gas porosity in ferrous molds.

High-quality bentonite increases pellet compressive strength by 40–60%, as shown in blast furnace efficiency studies. Leading producers use 0.5–0.8% bentonite concentrations to maximize induration furnace throughput while keeping dust generation below 1% during handling.

A North American operator achieved an 18% cost reduction in Marcellus Shale operations using ultra-purified sodium bentonite. With a swelling index of 1,500%, the material maintained hydraulic seal integrity for 12 months post-completion, outperforming conventional additives by 22% in preventing fracture closure.

More industries are turning to high quality bentonite these days as part of their green manufacturing approaches because it doesn't contain toxins and can be reused multiple times. Research published in 2025 by Sarypbekova and colleagues showed something pretty impressive actually - when used as sorbents, bentonite materials managed to pull out around 94 percent of heavy metals from waste water coming out of factories. This definitely helps companies work towards those circular economy goals everyone keeps talking about. These days, many manufacturers specifically ask for sodium bentonite when they need materials for landfill liners or cleaning up contaminated sites. Why? Because this particular type swells up quite a bit when wet (at least 28 mL per 2 grams) and doesn't react chemically with most substances, making it really effective for these kinds of environmental protection tasks.

Better processing methods like precision milling and organic modification can boost bentonite's CEC by around 15 to 20 percent. Drillers now use real time monitoring systems to keep fluid viscosity stable, staying within about 2% variation even when working through tough shale formations. A new trend in the industry involves polymer bentonite nanocomposites which show promise as performance boosters. These materials have been found to increase mold strength during metal casting processes by roughly 34%, plus they cut down on how much binder needs to be used according to recent findings from the Material Flexibility Report published last year.

Forward-thinking buyers are implementing blockchain-enabled tracking systems, which have reduced material rejection rates by 62% in automotive foundries (2023 Industrial Minerals Benchmark).

Hot News

Hot News2025-12-21

2025-12-15

2025-12-05

2025-12-02

2025-12-01

2025-11-19